Checks all, visible, or picked objects for common problems that could prevent data transfer.

Check only surfaces, only curves, or both. The default is Surfaces.

Check all objects, all visible objects, or picked (active) objects. The default is Visible.

Errors – Only show objects that failed one of the checks.

All – Show all objects even if they pass the checks.

The default is Errors.

Choose one of the construction presets from the drop down list. The list contains all the default and site based Construction Presets available from Preferences > Construction Options. The checks will be done using the tolerances from the preset you choose, rather than what is currently selected in the Construction Options window.

To use whatever set of tolerances is already selected in the Construction Options window (indicated by an arrow), choose Use Current Tolerances.

Check for rational geometry.

Check for periodic (closed) objects.

Use this check to find instances where trims have made a single surface look like separate surfaces, which can confuse some CAD software packages.

Check for multi-knots (multiple edit points at the same point in space that may create a sharp corner in a curve or surface).

Report objects with internal tangent discontinuities due to multi-knots.

Check for curves that are not planar. This option only appears when Check is set to Curves or Both.

Product Data Quality Recommended Checks

Off – No check is done for duplicate or embedded geometry.

Copies – Checks for curves or surfaces that are exact duplicates of each other. Copies have the same CVs, same knots, and same degree. If Report is set to All, the original object is marked “Original” in the Copies column of the report window.

Duplicates Within Tolerance – Checks for curves and surfaces that are duplicates of, or embedded into other curves and surfaces, within the tolerance given in the Duplicate Tolerance field.

This field appears when Duplicate Geometry is set to Duplicates Within Tolerance. Curves or surfaces that lie within that distance of each other are reported.

Check for edges (including trimmed edges) shorter than the distance specified in the text field.

Check for curves and surfaces whose interior span/isoparm configuration results in the length of a span (or the length of both opposing patch segments for surfaces) being smaller than the distance tolerance specified in the text field.

Check for curves and surfaces whose interior span/isoparm configuration results in knots being closer in parameter value than the tolerance specified in the text field.

Report surfaces that have a radius of curvature smaller than a user-defined value. The smallest radius found on those surfaces is reported.

Report curves, surface boundaries, or trimmed surface boundaries that contain interior self-intersections. A self-intersection refers to the curve or surface boundary intersecting itself at one or more locations that are not both endpoints.

Report trimmed surfaces containing boundaries that intersect other boundaries on the same surface, within the tolerance supplied in the text field.

Check for objects with a degree higher than the number specified in the text field.

Report curves and surfaces that contain a number of spans exceeding the value specified in the text field.

Report surfaces or planar curves that have more than a user-defined number of inflections (change in curvature sign) over their entire length (or width for surfaces). The maximum number of inflections allowed is entered in the text field (default is 3).

This field only appears when Surface Curvature Waviness is ON. When turned on, it controls the maximum number of inflections per span allowed for a surface to pass the waviness test, in addition to the overall number of inflection permitted (see previous option). The default is 1.

Check for surfaces whose normal direction is inconsistent with the normal direction of adjacent surfaces.

) must be larger than the Maximum

Gap Distance for this check to find inconsistent normals.

) must be larger than the Maximum

Gap Distance for this check to find inconsistent normals.

Report objects that exceed a user-defined tolerance for positional continuity between adjacent curves or surfaces.

The tolerance value is

given by Maximum Gap Distance in the

Tolerances Continuity section of Preferences > Construction Options  .

.

) must be larger than the Maximum

Gap Distance for this check to find gaps.

) must be larger than the Maximum

Gap Distance for this check to find gaps.

See Maximum Gap Distance.

Report objects that exceed a user-defined tolerance for tangent continuity between adjacent curves or surfaces.

The tolerance value is

given by Continuity Angle in the Tolerances

Continuity section of Preferences > Construction Options  .

.

) must be larger than the Maximum

Gap Distance for this check to find tangent discontinuities.

) must be larger than the Maximum

Gap Distance for this check to find tangent discontinuities.

See Continuity Angle.

Report objects that exceed a user-defined tolerance for curvature continuity between adjacent curves or surfaces.

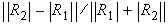

The curvature deviation is calculated as:

The tolerance value is

given by Continuity Curvature in the

Tolerances Continuity section of Preferences > Construction Options  .

.

) must be larger than the Maximum

Gap Distance for this check to find curvature discontinuities.

) must be larger than the Maximum

Gap Distance for this check to find curvature discontinuities.

See Continuity Curvature.

Maximum angle allowed between the tangents (or normals) of objects for them to be included in the G1 continuity test.

Maximum curvature deviation allowed between objects for them to be included in the G2 continuity test.

.

.