If, after setting up a Transformer Rig and clicking Go, the surfaces do not update as expected,

Each case is different — it all depends on the geometry and the intent. As you gain experience using the tool, you will develop a better feel for which method works best.

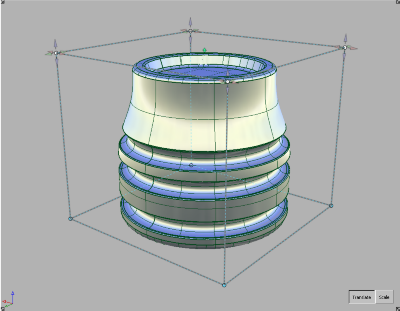

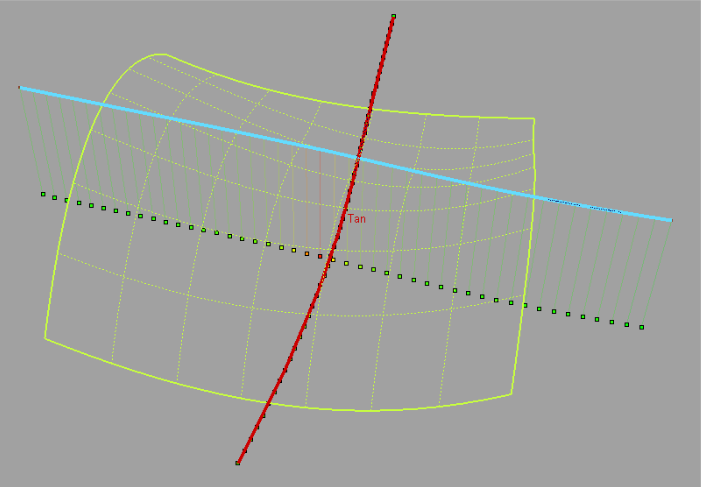

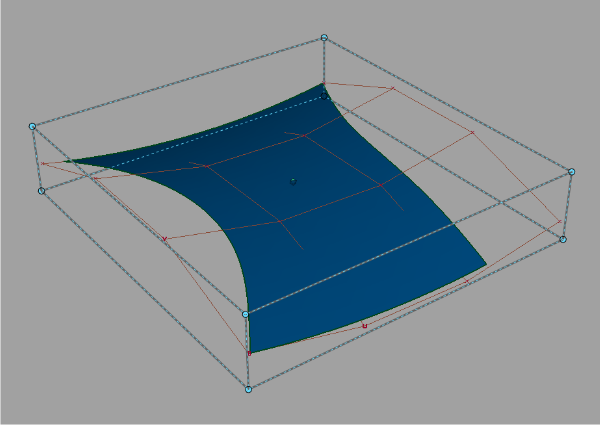

In the following image, the modifier and the constraint intersect. Notice that close to the intersection point, the visualization turns from green to yellow to red, to indicate that there is a conflict.

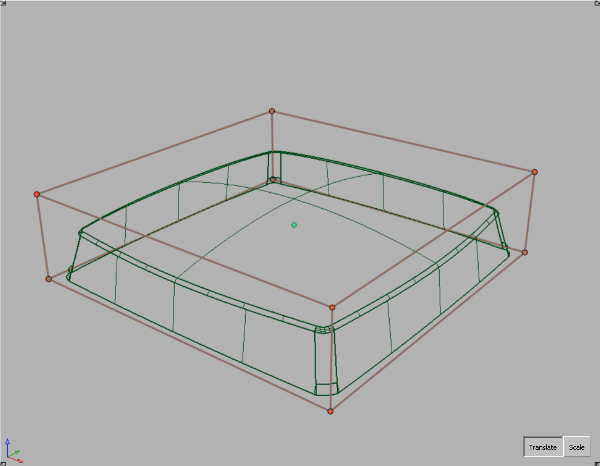

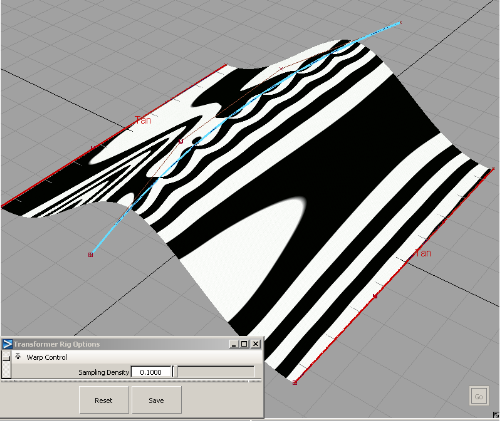

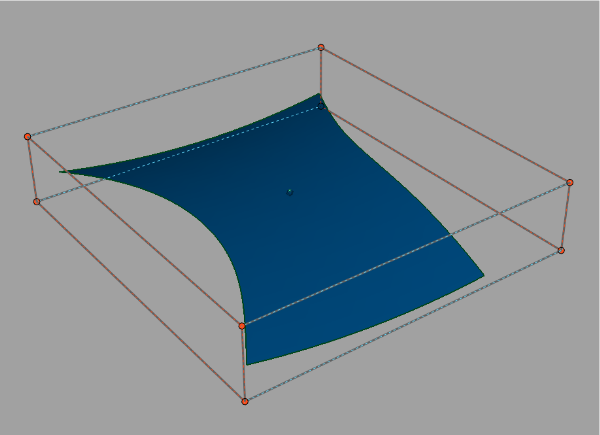

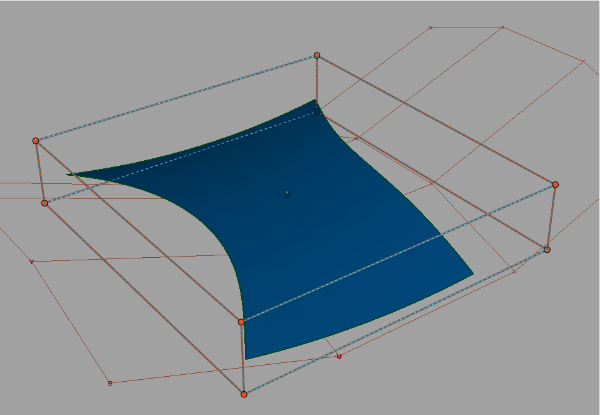

If you turn on the CVs of the surface, you see that the surface is a trimmed surface, and the removed parts intersect with the lattice.

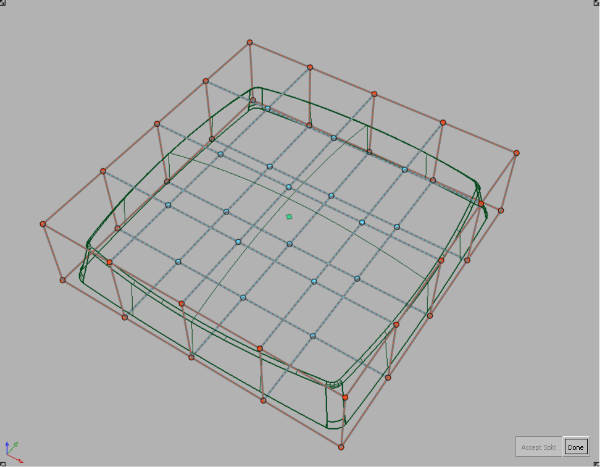

Shrinking the trim will fix this problem.

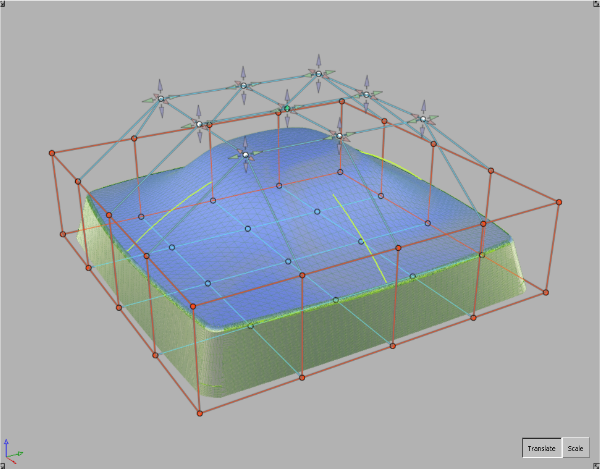

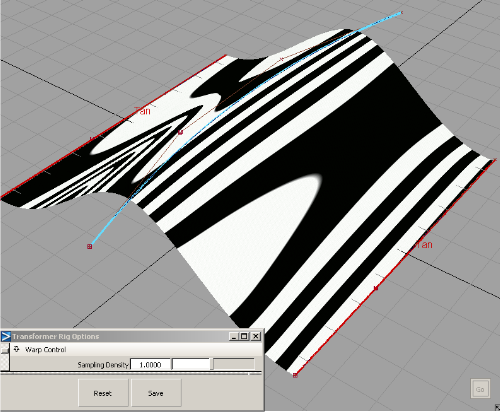

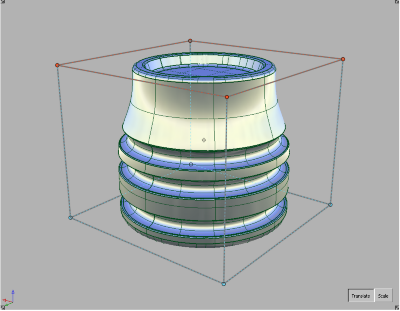

Translating the top of the lattice upwards solves the problem.